Andreas Haaß

General Manager

INP Deutschland GmbH

Werkstraße 5

67354 Römerberg

Germany

Tel. +49 6232 6869-0

andreas.haass @

@ inp-e.com

inp-e.comvCard

INP International Projects: We offer you more than 35 years of experience in global power plant, large-scale installation construction and the power industry, combined with the reliability of an owner-managed company.

INP offers you an interesting professional future with bright prospects. Now you can become part of our international team.

INP is your reliable partner in the fields of power generation, transmission and distribution, as well as green energy and construction and infrastructure.

![]() We stand for the values of owner-managed SMEs: reliability, responsibility, quality and adherence to deadlines.

We stand for the values of owner-managed SMEs: reliability, responsibility, quality and adherence to deadlines.![]()

![]() Professionalism and reliability are what our customers appreciate. And this has been so for over 30 years.

Professionalism and reliability are what our customers appreciate. And this has been so for over 30 years.![]()

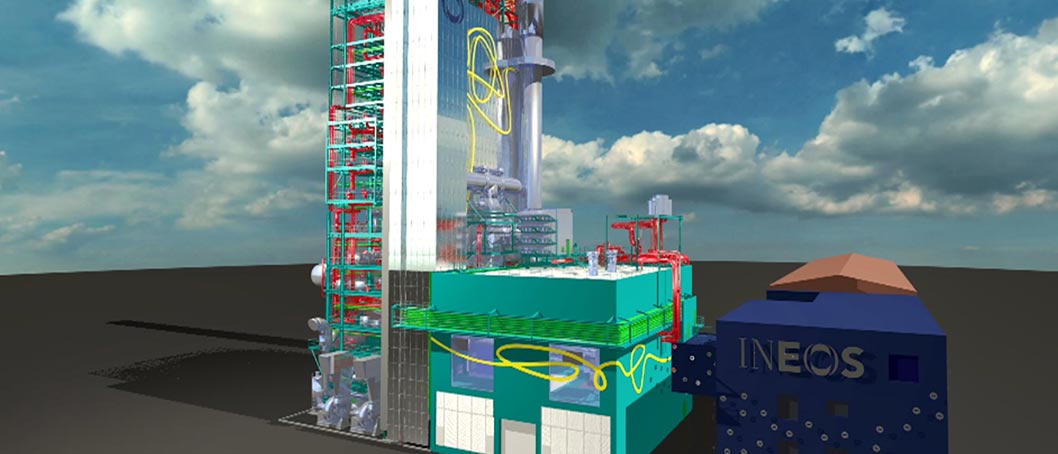

Location: Cologne-Worringen, Germany

System/Technology: DCS: SPPA T3000; TLT DT: PCS7; TLT GT: Mark VIe

Services: Production monitoring, Commissioning, Project management, Quality assurance, Documentation, Basic-engineering and pre-engineering, Detail engineering, Training, Solution development / Feasibility studies

Industry Branch/Type of Plant: Large Plants, Green Energy, Chemical plants

Client: INEOS Köln GmbH

Activity period: since 2019

INP was commissioned to plan and implement the EMSR components of a state-of-the-art gas and steam plant to ensure a sustainable and efficient energy supply for INEOS‘ production facilities in Cologne. Our in-depth technical expertise and innovative approach contributed significantly to the successful implementation of this project.

Thanks to our precise planning and comprehensive support, a plant was completed, which operates at an efficiency rateof over 90 percent and enables reliable thermal utilization of residual materials. This not only enhances the economic efficiency of the plant, but also makes a significant contribution to sustainability.

As a reliable partner of INEOS in Cologne, we contributed our comprehensive expertise and actively shaped the project during all phases. Our range of services included:

The successful implementation of this project once again underscores INP‘s outstanding expertise in the field of highly complex control technology and energy plant design. Thanks to our comprehensive expertise and practical approach, we were able to master the technical challenges and also maximize the added value for our customer.

We are proud to have supported INEOS in Cologne as a reliable partner and to have jointly created a sustainable, efficient, and innovative energy solution.

To optimize your visit on our website we use cookies. Some of them are necessary whereas others are helping us to improve and customize the user experience of our website. For this purpose, cookies are used to collect and analyze pseudonymized data of website visitors. You can at any time change or withdraw your consent from the use of cookies.

Further information regarding cookies in this website can be found in our privacy policy